The integration of external content may be switched on or off

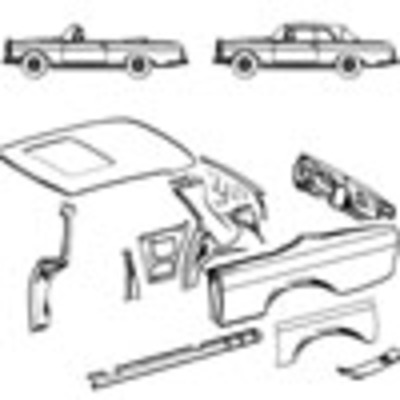

Mercedes W111 W108 W114...

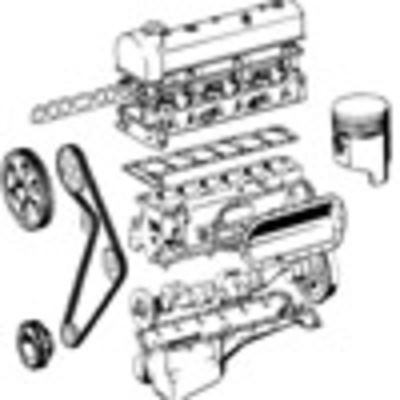

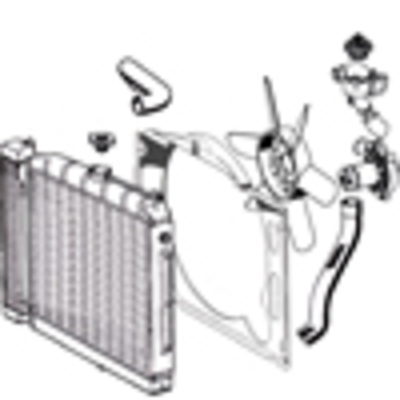

15 Ignition, Generator, Starter for Petrol engines R4 and R6

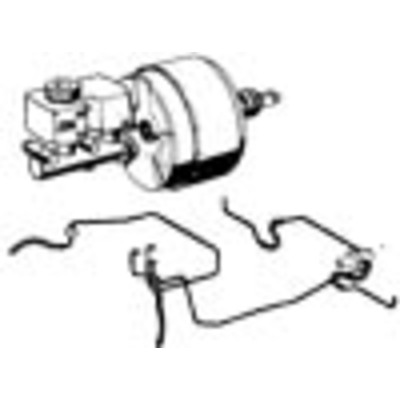

32/35.i Info Hyd. pneum spring assy W110, W111, W108

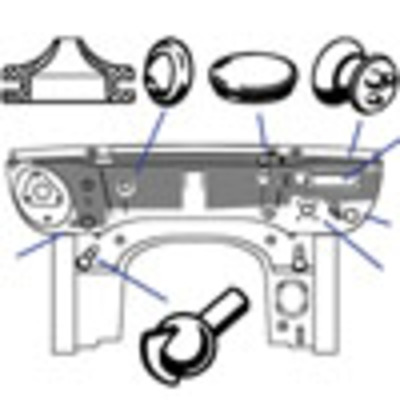

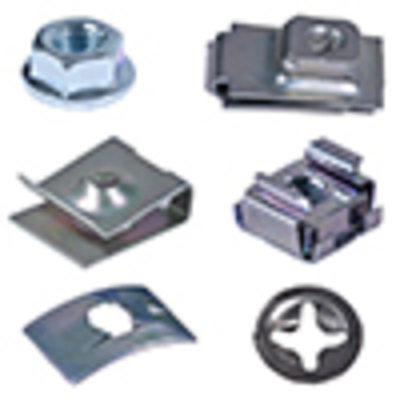

Easy view display for older MB cars: all bolts with ball band and thread M12 x 1.5 and key width 17. This makes it easier to sort LOOKING AT TOTAL LENGTH (length over everything). Various axle/wheel combinations led to the bolts shown here between 1959 and 1989. As a rule of thumb: when screwing in, the bolt should reach its seat about 6 to 7 whole rotations into the thread. with less load-bearing thread, the load-bearing capacity is not achieved, with longer screwing there can be contact with other parts (endangered: rear handbrake, front brake disc e.g. with type 230SL). In the mid-1980s, a system change over MB front axles took place: former wheel hub flange (threaded seat) attached to the rim (brake disc screwed separately on the inside), later brake disc on wheel hub, between rim and threaded seat. (For the hub diameter, see also the information board on brake discs). The design of rim plates is not only material dependent, but different manufacturers (example baroque replica) designed their own plates with consequences for the bolt length and deviations from the MB principle ball band /SW17

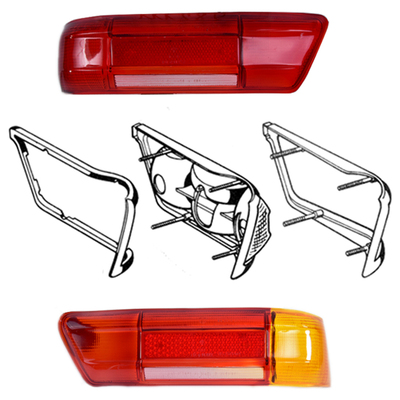

97 flexible hoses, by meter, assorted by inner diameter